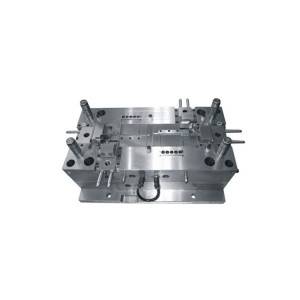

P&M Plastic Box TV Shell Plastic Spoon Mould Maker

TIPS:

We have different kinds of mold cases, 13 years of mold making experience, 2 large factories of our own,

and hundreds of professional engineers and designers. Don't worry about mold quality and quantity.

We can provide one-stop service, customize the products you want, and give you the most suitable quotation and the most satisfactory service.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Shipping:

Express way can choose any transportation method according to your requirements.

We generally choose sea transportation, which is the cheapest way.

We have professional freight forwarders, and we can be completely assured of product protection.

Shipping time by sea is generally 10-20 working days.

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),

South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould,Plastic Product,Metal Product,Dental Product,CNC machining

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products.

We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian