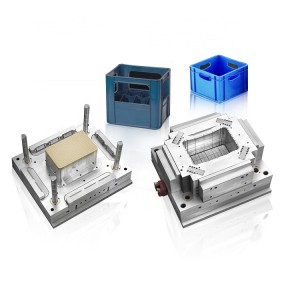

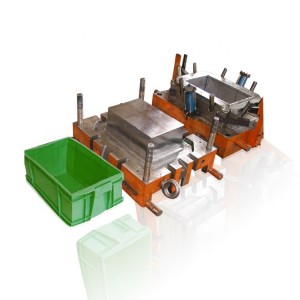

Plastic Injection Mold For PC Box, Food Box Plastic Box Mould Maker

Product Description

Plastic molding Specification

| Item | Plastic Mould Box |

| We promise | All customer-centric, never for short-term profit, and sell long-term benefits |

| We produce | Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

| Pls provide | 20-35 Days |

| Product time | 7-15 Days |

| Moud precision | +/-0.01mm |

| Mould life | 50-100 million shots |

| Mould cavity | One cavity, multi-cavity or same different products be made together |

| Mould material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Runner system | Hot runner and cold runner |

| Base material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Standard | HASCO, DME or dependent upon |

| Software | CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

| Quality system | ISO9001:2008 |

Packing & Delivery

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould,Plastic Product,Metal Product,Dental Product,CNC machining

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design – 3d printing – mold making – plastic injection

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian