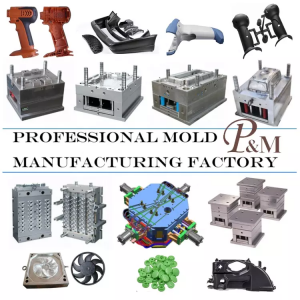

plastic spoon mould suppliers plastic moulding dies factory china 3d mold design factory

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and dimensions of the products you want to make, we will design drawings and make molds for you, and hope to become a long-term partner with you.

We are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, we do not have a minimum order quantity, tell us your needs, we can provide you with the most professional service.

One-Stop service:

3D design-3D printing-Mold design-Mold making-Plastic Injection Production-Silk screen printing.

Plastic Injection Mould making

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample’s inspection report&injection parameters with the sample to you! 7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times 10. Package: Plywood case, anti-rust paint