Welcome to visit P&M

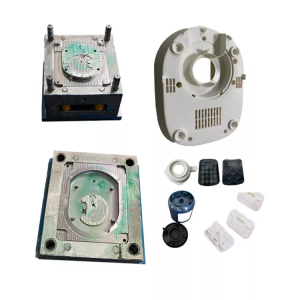

ABS plastic parts,Cheap plastic injection molding for electronic housing

High quality Medical device plastic parts made by plastic injection mold/mould for plastic injection molding service

Design:

We have professional engineers design team,and can use CAD,Pro-E,UG,Solidworks etc.

Before the project started:

1, If you have 3D STEP/IGES/X_T drawing or 2D drawing, please directly send to us

before quotation, then we will do DFM and mould design for you.

2, If you have samples no drawings, please directly provide us samples, we can design 3D for you,and quotation.

We are committed to producing high-quality molds and providing the best service at the best price. You can provide us with pictures and dimensions of the products you want to make, we will design drawings and make molds for you, and hope to become a long-term partner with you

We are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, we do not have a minimum order quantity, tell us your needs, we can provide you with the most professional service.

One-Stop service:

3D design-3D printing-Mold design-Mold making-Plastic Injection Production-Silk screen printing.

Plastic Injection Mould making

1.Samples/Drawing &Requirement from you 2.Mould design:we will Communicate and Exchange the opinion with you after you place order. 3.Material Purchase:Steel cutting and Mould base tooling. 4.Assembling. 5.Inspection of mould : following and controlling the tooling processing. 6.Mould testing:We will inform you the date.Than will send the sample’s inspection report&injection parameters with the sample to you! 7.Your instruction &confirmation for shipment. 8.Ready made mould before packing. 9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification

1. Professional manufacturer,design,production injection mould and stamping mould quality control 2. rich export experience plastic injection mould and stamping mould 3. Reasonable price of design mould 4. Cavities: single or as per your requirements cavity 5. Treatment: S45C Pretreat>25Hrc,And Nitriding 6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available 7. Standard:DEM ,HUSKY,available 8. Hot runner: according to your demand 9. Life time: >300 Thousand Times 10. Package: Plywood case, anti-rust paint

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment. If there is a problem with the product, we will seek a solution actively and take responsibility to the end. Please choose us and let us be partners in long-term cooperation.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mould,Plastic Product,Metal Product,Dental Product,CNC machining

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design – 3d printing – mold making – plastic injection

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,French,Russian

6.What are the characteristics of your service

1. Your inquiry related to our products or prices will be replied within 24hours 2. Welltrained and experienced staffs to answer all your enquiries in fluent English. 3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.

Previous: P&M high quality cheapest Tool Kit Plastic Professional Injection Mould

Next: High precision plastic injection mold for plastic laptop shell OEM plastic custom molding factory China Mould Maker