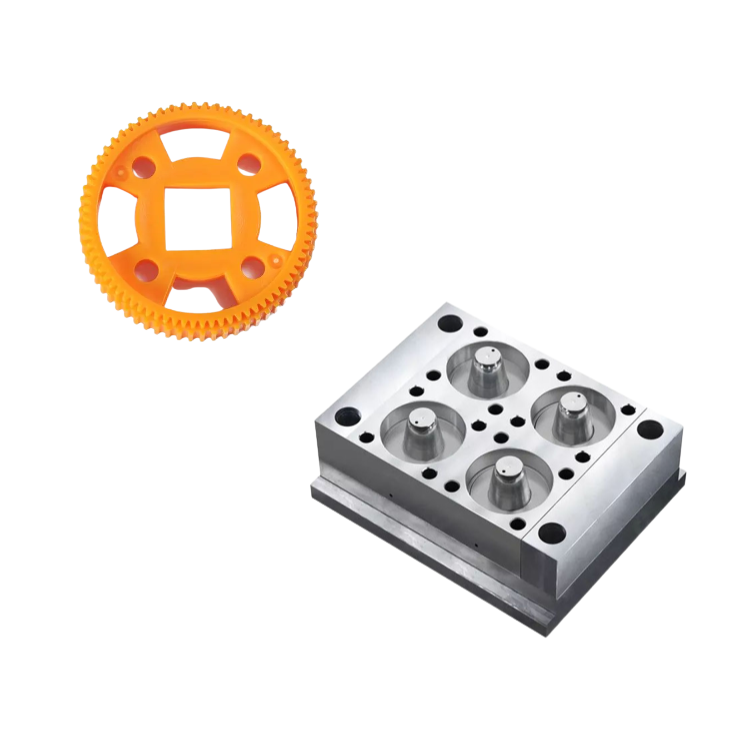

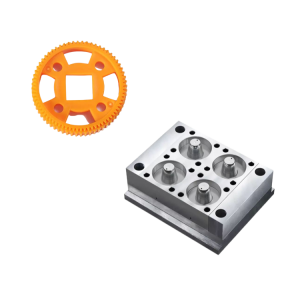

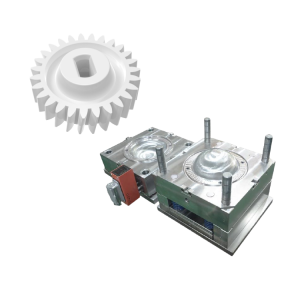

Customized nylon HDPE gear moulds for professional mini gears in China

Customized nylon HDPE gear moulds for professional mini gears in China

To be able to ideal meet up with client’s needs, all of our operations are strictly performed in line with our motto “High High-quality, Competitive Cost, Fast Service” for Factory Promotional China Free Sample Fast Delivery Die Casting Mould Plastic Mold Injection Molding Die Casting Mould Service for Car Flange Clutch Housing Car Steering Gear Car Bracket, We are wanting ahead to setting up cooperative associations along with you. Please call us for more information and facts.

Factory Promotional China Gearbox Housing Mould, Crankcase Mould, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs.

|

Product Name

|

High Quality Plastic Injection Mold and Molding Manufacturer

|

|||

|

Mold Material

|

S136/2344/718/738/NAK80/P20, etc.

|

|||

|

Plastic Material

|

ABS, PP, PC, PVC, POM, TPU, PC, PEEK,HDPE,NYLON, Silicone, Rubber, etc

|

|||

|

Mold Base

|

LKM, HASCO, etc.

|

|||

|

mold Life

|

3k-800k shots (depend on your environment)

|

|||

|

Mould Precision

|

+/-0.01mm

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity.

|

|||

|

Runner System

|

Hot runner and cold runner

|

|||

|

Sureface Treatment

|

Polishing/smooth,texture/frosted, painting, plating, printing , etc.

|

|||

|

File Format

|

STEP, STP, STL, X-T, IGS, PDF,JPG,etc.

|

|||

|

Custom Feature

|

According to your 2D/3D Drawing or sample provided

|

|||

|

Quality Assurance

|

ISO9001: 2015, SGS, ROHS, TUV,etc

|

|||

|

Our Equipments

|

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 30-1400T available.

|

|||

|

Main Field

|

Home appliance, Medical device, Electronic device, Automotive parts, Tele-communication, Lighting control equipment, digital device, Robots, etc.

|

|||